Custom Engineering

Part Processing and Tooling Solutions

Custom Engineering Solutions for Precision Tooling & Fixturing

At JPT, we specialize in solving complex machining challenges through custom-engineered cutting tool design and part fixtures. Our expertise ensures high-quality parts, optimized cycle times, and cost-effective solutions—delivered on time, every time.

Why Partner with JPT?

We tackle your toughest machining problems by:

- Analyzing Processes (including alternative methods).

- Recommending Improvements to boost efficiency and part quality.

- Designing for Excellence with best-practice engineering.

- Manufacturing & Installing precision tooling tailored to your needs.

- Measuring Results with data-driven validation.

- Providing Ongoing Support to ensure long-term success.

When to Involve JPT

Maximize your ROI by engaging us early:

- Before selecting machine tools or part processes—optimize from the start.

- When parts aren’t meeting quality/cycle time goals—diagnose and resolve.

- For repairing, replacing, or sourcing tooling—extend tool life or find alternatives.

- When competitive edge matters—meet tight deadlines without sacrificing quality.

Your Challenge, Our Solution

From prototype to production, JPT delivers custom tooling that performs. Let’s engineer a better way—contact us today to discuss your project.

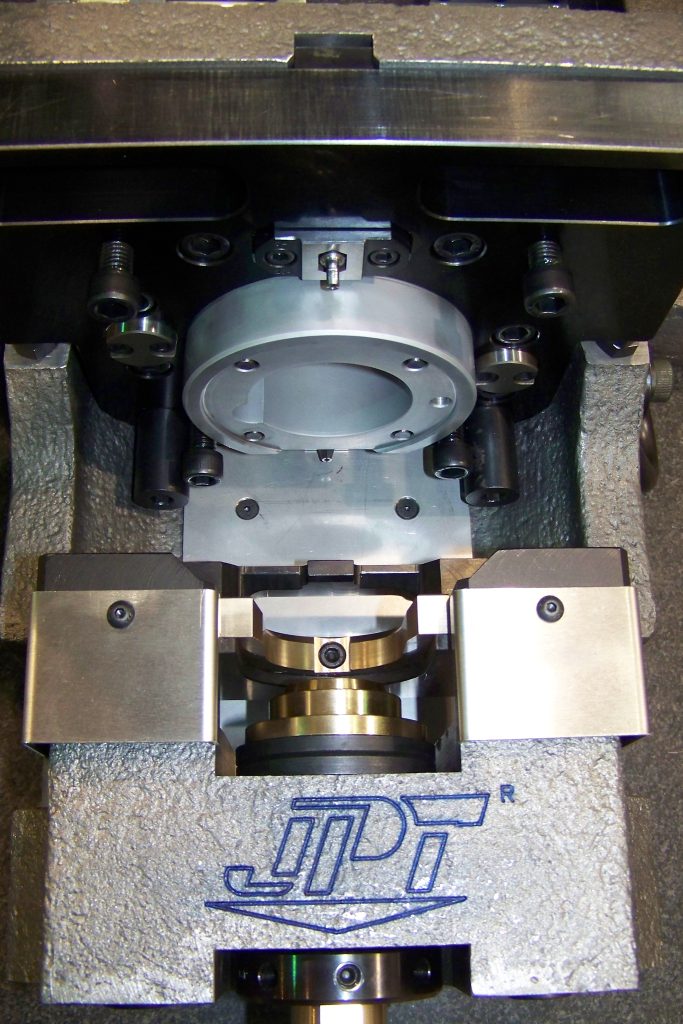

Above: A sample of JPT’s custom tooling solutions—each designed to solve unique machining challenges with precision and efficiency.

Precision Engineered Cutting Tools & Fixtures

At JPT, our engineered solutions deliver three critical advantages – all carefully synchronized by design for your specific applications:

- Optimized Cycle Times

Reduce machining hours without sacrificing quality.

Synchronized by design: We calculate ideal feed/speed ratios and tool paths to maximize efficiency while protecting tool integrity. - Improved Part Accuracy

Achieve tighter tolerances with durable tooling.

Synchronized by design: Our tools maintain precision through optimized rigidity and wear-resistant materials. - Cost-Effective Production

Extend tool life and minimize downtime.

Synchronized by design: We specify geometries and coatings that reduce wear while maintaining cutting performance. - Precision tool balance by design

Balancing to ISO 1940-1 G2.5, reduced harmonics, balance cutting forces enabling aggressive chatter free machining.

Synchronized by design: Computer balanced designs employing artificial intelligence and myriads of materials. - Fixturing Synergy

Tool specific workholding to dampen vibration, enhance tool life and quality.

Synchronized by design: Quick-change modular for family of parts and tooling optimization.

Why “Synchronized by Design” Matters:

- Prevents over-engineering (no unnecessary costs).

- Avoids single-parameter optimization that hurts overall performance.

- Delivers tools that perform optimally in YOUR specific application.

- Machining efficiency equals Process + Tool + Fixture + Machine Synchronization.

- Workholding equals Rigidity / Accessibility / Repeatability / Thermal Stability.

How We Deliver Results

- Analyze your process, machine tool, material, and pain points.

- Design tooling with best-practice engineering.

- Manufacture & Test for best performance.

- Support your team through installation and beyond.

Featured Fixture: Precision-machined fixture designed for automotive parts maker ensuring repeatable accuracy and reduced setup times.

Custom Engineered Workholding & Fixturing Solutions

At JPT, we engineer robust fixturing solutions that transform your production process. Our custom fixtures are built to:

- Eliminate part movement – Secure even the most complex geometries.

- Reduce operator dependency – Streamline changeovers with foolproof designs.

- Maximize spindle uptime – Durable construction for continuous production.

Our Fixture Design Advantage

✔ Application-Specific – Tailored to your part and machine tool.

✔ Error-Proofed – Built-in features to prevent misloading.

✔ Future-Ready – Designed for easy modification as needs evolve.

Above: JPT’s custom fixture solutions in action – delivering stability and precision for demanding machining applications.

Ready to Optimize Your Machining Process?

JPT doesn’t just provide tools—we deliver engineered solutions that solve your specific production challenges.

Next Steps:

- Share Your Blueprint – Send us your part print or sample.

- Diagnose Together – We’ll analyze pain points and opportunities.

- Build & Validate – From prototype to full production support.

Why Wait?

☑ Proven Expertise – Decades of specialty tooling experience.

☑ Guaranteed Fit – Custom solutions backed by performance data.

☑ Total Support – From design to production floor implementation.

Explore Engineered Solutions

See our proven cutting tools and fixturing systems in action.

Over 50-years, cutting tool design and manufacturing.

Visit our Products Page

Request a Consultation

Need a custom solution? Contact JPT to discuss your application—we’ll engineer the right tool for your job.

For more information on our engineering services feel free to contact us for a free no obligation proposal.

To learn more about JPT's Custom Engineering Services - contact us today